Zinc dialkyldithiophosphates (ZDDPs) are widely used in many commercial lubricant formulations as anti-wear additives and friction modifiers. The extensively accepted anti-wear mechanism of ZDDP is that a layer of tribofilm with low hardness and elastic modulus is generated on the contacted substrate, surfaces of friction pairs during sliding process. This tribofilm is capable of preventing the harder substrate metallic surfaces from direct contact, and hence results in mild wear.

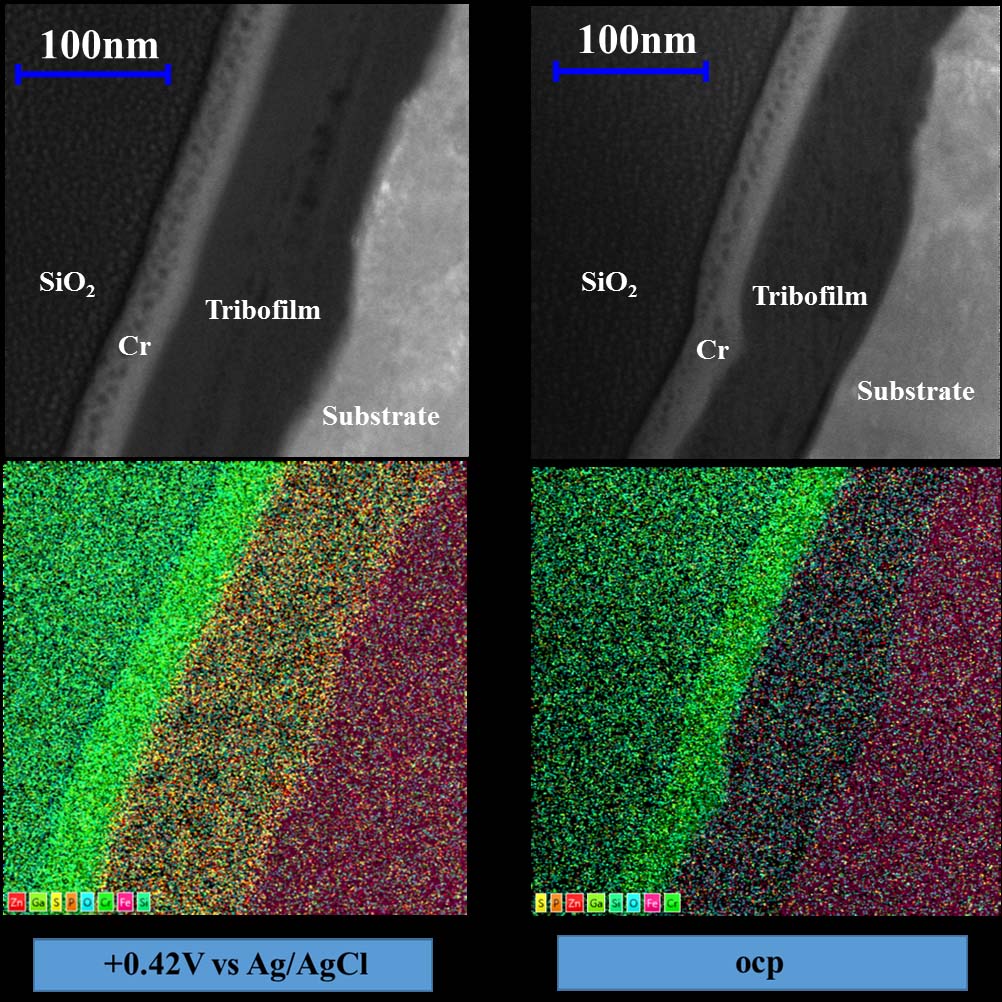

However, ZDDP additive has a drawback because of its high content of sulfur and phosphorous elements, both of which poison catalytic converters in automotive engines, and thus are harmful to the environment. Therefore, it is meaningful to cut the ZDDP concentration as low as possible. In this study, the electrichemical method was employed to promote the tribofilm formation during friction process in lubricant with relatively low ZDDP concentration. As a results, when positive potentials were applied on the surface, the anti-wear and friction modified effects are almost comparable with that in the lubricant blended with more than twice the weight fraction of ZDDP under the ocp. Furthermore, SEM and TEM were used to characterize the tribofilms under different surface potentials.The results show that good tribofim formation state requires an appropriate potential interval. Within this potential interval, the thickness of ZDDP tribofilm increased by 30% comparing with that under the OCP.

This paper is published on the Tribology International in May, 2018.

Article link: https://www.sciencedirect.com/science/article/pii/S0301679X18302536

Fig.1.Variations of COF and wear under lubrication with different ZDDP concentrations.

Fig. 2. COF and wear variations under different surface potentials (2% mass ZDDP).

Fig. 3. SEM images and EDS results under various surface potentials.

Fig. 4. Cross-sectional TEM images and EDS elemental maps under different surface potentials.